Call us now!

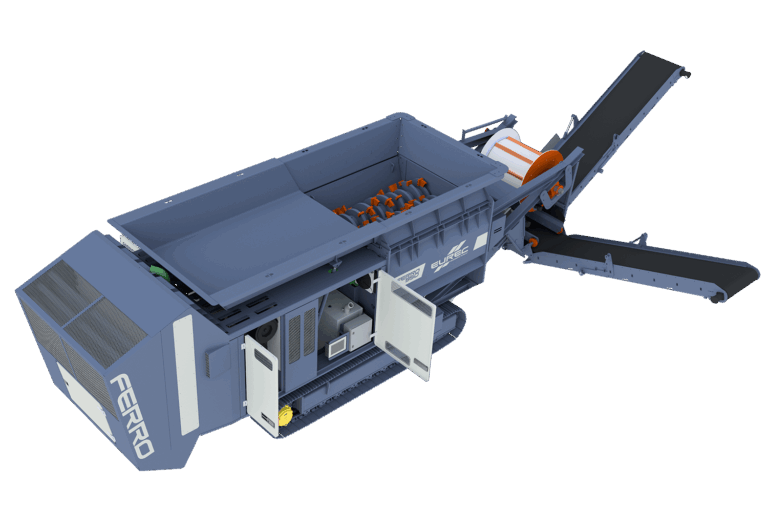

Two-Shaft Shredder

FERRO 950 (FE-Version)

The FERRO 950 FE version has been specially designed for demanding applications with a high ferrous content. With a reinforced design, a powerful shredding system and an integrated magnetic drum for separating ferrous and non-ferrous components, the most powerful shredder on the market is suitable for extremely resistant material flows such as broken concrete and concrete railway sleepers with reinforcing steel, end-of-life vehicles and scrap metal.

The FE version of the FERRO 950 is also supplied in asynchronous operation as standard – ideal for applications with a high proportion of contaminants and changing material flows.

| Dimensions | |

|---|---|

| Length | 15,600 mm / 11,500 mm (transport) |

| Width | 6,700 mm / 3,000 mm (transport) |

| Height | 3,650 mm / 3,650 mm (transport) |

| Weight | approx. 53,000 kg |

| Discharge height | 3,500 mm (FE) / 2,400 mm (NF) |

| Drive | |

| Engine type | John Deere JD 18 |

| Power | 677 kW / 908 PS |

| Emission standard | Stage V / EPA Tier IV (without AdBlue) |

| Torque | 4,250 Nm |

| Fuel capacity | 1,200 l |

| Shredding Unit | |

| Hopper volume | 9.5 m³ (incl. tilting hopper) |

| Shaft length | 2,500 mm |

| Shaft diameter | 860 mm |

| Weight | 3,500 kg / shaft |

| Rotation speed | 15 – 45 rpm |

FERRO 950 FE-Version

Applications

Concrete and Concrete Railway Sleepers

... demolition material, prefabricated parts, broken concrete, concrete sleepers with reinforcing steel

Cars and Light Scrap

... car bodies, mixed scrap, light metal parts

Rubber and

(AS/EM) Waste Tires

... conveyor belts, tires for earthmoving machines and agricultural tractors

Engine Blocks

... motors, gearbox housings, castings

White Goods

... refrigerators, washing machines, cookers, electrical appliances

Aluminium

Aluminium

... profiles from construction and industry, sheet metal, beverage cans, die-cast parts

FERRO 950 FE-Version

Technical Features

Integrated magnetic drum

Compared to the classic overbelt

magnet, the drum is significantly

more resistant without wear-prone

rubber belts. This enables efficient

separation of the shredded material

into ferrous and non-ferrous

components.

Touch display control

The structured control panel can

be used to precisely regulate the

rotation speed of the tool shafts

and the belt speed. Sensors provide

accurate error displays and enable

simple, intuitive operation for

daily use.

Demand-orientated

fan control system

The intelligent fan control ensures

constant motor cooling with reduced

dust and noise generation. This means

that the motor always operates

within the optimum temperature

range - efficiently and reliably, even

under high loads.

Exchange system with

mounting cylinder

Both shredding shafts are first

inserted individually into the

appropriate device. A hydraulic

assembly cylinder then inserts both

shafts evenly into the cloverleaf

clutch - simply, quickly and safely.

Interested in the EuRec FERRO 950 FE?

Contact us – our team will be glad to advise you on all questions relating to performance, equipment and possible applications.