Call us now!

Two-Shaft Shredder

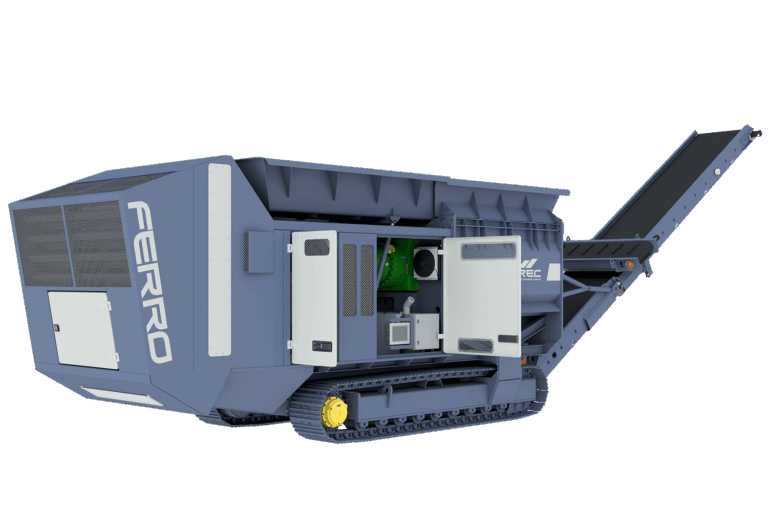

FERRO 950 (NF-Version)

The EuRec FERRO 950 is one of the most powerful shredders among the slow-speed two-shaft shredders and was developed for particularly demanding applications. Equipped with a powerful John Deere diesel engine, an extremely robust design and high throughput, it is particularly impressive where reliability, power and wear resistance are required.

The FERRO 950 is supplied with an asynchronous shaft configuration as standard – ideal for the efficient shredding of resistant materials with a high proportion of impurities.

| Dimensions | |

|---|---|

| Length | 16,400 mm / 11,350 mm (transport) |

| Width | 3,000 mm / 3,000 mm (transport) |

| Height | 3,650 mm / 3,650 mm (transport) |

| Weight | approx. 49,000 kg |

| Discharge height | 5,500 mm |

| Drive | |

| Engine type | John Deere JD 18 |

| Power | 677 kW / 908 PS |

| Emission standard | Stage V / EPA Tier IV (without AdBlue) |

| Torque | 4,250 Nm |

| Fuel capacity | 1,200 l |

| Shredding Unit | |

| Hopper volume | 9.5 m³ (incl. tilting hopper) |

| Shaft length | 2,500 mm |

| Shaft diameter | 860 mm |

| Weight | 3,500 kg / shaft |

| Rotation speed | 15 – 45 rpm |

FERRO 950 NF-Version

Applications

Commercial Waste

... mixed waste from industry and trade, bulky waste, packaging waste, plastics

Rubber and Waste Tires

... car and truck tires, tractor tires, conveyor belts, rubber mats

CFRP/GFRP Waste

... Wind turbine rotor blades, boat hulls, lightweight panels, composite materials

Waste Wood

... pallets, chipboard, furniture remnants, construction timber, formwork

Wooden Railway Sleepers

... Tar-oil impregnated railway sleepers, impregnated wooden beams, pressure-impregnated construction timber

Aluminium

... Profiles from construction and industry, sheet metal, beverage cans, die-cast parts

FERRO 950 NF-Version

Technical Features

Touch display control

The structured control panel can

be used to precisely regulate the

rotation speed of the tool shafts

and the belt speed. Sensors provide

accurate error displays and enable

simple, intuitive operation for

daily use.

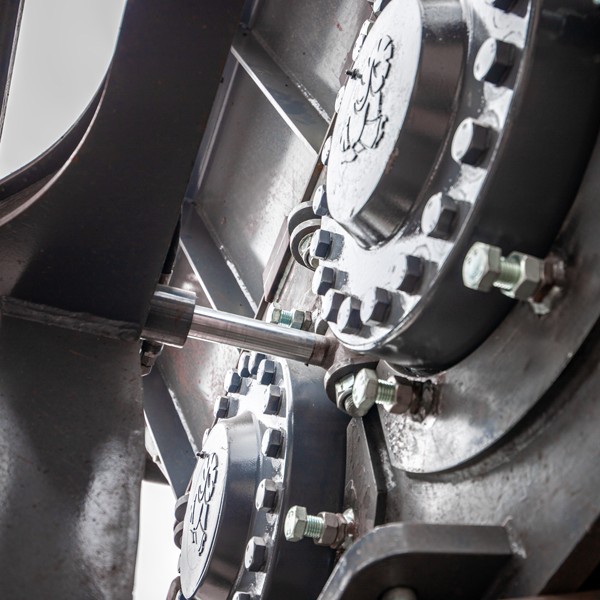

Exchange system with mounting cylinder

Both shredding shafts are first

inserted individually into the

appropriate device. A hydraulic

assembly cylinder then inserts both

shafts evenly into the cloverleaf

clutch - simply, quickly and safely.

Demand-orientated

fan control system

The intelligent fan control ensures

constant motor cooling with reduced

dust and noise generation. This means

that the motor always operates

within the optimum temperature

range - efficiently and reliably, even

under high loads.

Hydraulically damped

side combs

In case of excessive pressure on

the tool shafts, the side combs

open automatically and release the

material throughput. This prevents

blockages and noticeably reduces

the load on the shredding unit.

Interested in the EuRec FERRO 950 NF?

Contact us – our team will be glad to advise you on all questions relating to performance, equipment and possible applications.